+86 16692292870

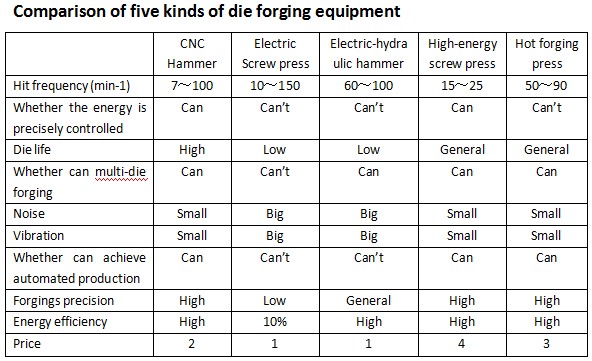

Comparison of several die forging equipment

Die forging machine include CNC fully hydraulic closed die forging hammer, Electric Screw Press, Electric-hydraulic closed die forging hammer, Hot die forging press, High-energy screw press, etc

1. CNC fully hydraulic closed die forging hammer

Advantage:

1), Hit energy and working procedures are intelligent controlled. Hit energy is precision digital controlled;

2), High hit frequency;

3), Can be multi-die forging;

4), High precision forging;

5), High die life;

6), Ejection system;

7), Easy to achieve automated production;

8), Equipment investment is moderate.

2. Electric Screw Press

Advantage:

1), The structure is simple;

2), Low speed, easy operation;

3), A wide of forming processes, can be used for forging, trimming, bending and other processes.

Disadvantage:

1), Due to the existence of the screw, the ability to withstand eccentric load is poor, generally only for single-bore forging; not suitable for a heating to complete a few processes (such as the removal of oxide, pre-forging and trimming);

2), When using the screw press for final forging, need other equipment to complete the auxiliary process, the production line equipment complex, the entire line investment is high.

3), Low hit frequency, low production efficiency;

4), Ordinary screw press low energy efficiency, only about 10%.

3. Electric-hydraulic closed die forging hammer

Advantage:

1), Simple structure, low maintenance costs;

2), Easy to operate, flexible and strong;

3), Can multi-die forging, don't need pre-forging equipment;

4), The small hammer forge big forgings;

5), Less equipment investment.

Disadvantage:

1), Can't precisely control the hit energy;

2), When final forging, easy occur the cold phenomenon, mold life is low;

3), big noisy, strong ground vibration;

4), can't achieve automated production.

4. Hot die forging press

Advantage:

1), Large rigidity,stable performance and equality of forging quality;

2), Ejection system;

3).High hit frequency;

4).Easy to achieve automated production.

Disadvantage:

1), Great investment;

2), Due to the fixed slider stroke, the mold is not easy to adjust, it is only used for mass production of forgings;

3), The upper and lower ends of the blank oxide layer easily pressed into forging surface.

5. High-energy screw press

Advantage:

1), High energy utilization rate;

2), Good slider-oriented, strong anti-eccentric load capacity, can achieve multi-die forging.

Disadvantage:

1), Low hit frequency, usually 20 /min;

2), Expensive.

Anyang Forging Press’s Die Forging Machine include CNC fully hydraulic closed die forging hammer, Electric Screw Press, Electric-hydraulic closed die forging hammer etc, if you need this machine, don’t hesitate to

Contact:Bellea Yuan

Tell: 0086-3389658

Whatsapp : 008618317777560

WeChat:008618317777560

Email : bellea@anyanghammer.com

Website : http://www.cncforginghammer.com/

Facebook :https://www.facebook.com/profile.php?id=100015348467644

Youtube:https://www.youtube.com/channel/UCkgrnAEsX7QRlRe0ylW6GiA?view_as=subscriber

E-mail:felicia@anyanghammer.com

E-mail:felicia@anyanghammer.com

WhatsApp: +86-13619834657

WhatsApp: +86-13619834657

Add: West Part of Changjiang Road, High-Tech Zone, Anyang,China.

Add: West Part of Changjiang Road, High-Tech Zone, Anyang,China.

2001-2019 All Rights Reserved by Anyang Forging Press ( Group) Machinery Industry Co.,Ltd. Site Index | Product Index

Pre:

Pre:  Next:

Next: